Product Center

ACU10F

Category:

Product attachment:

Product Description

- Product Description

-

I. Product Overview

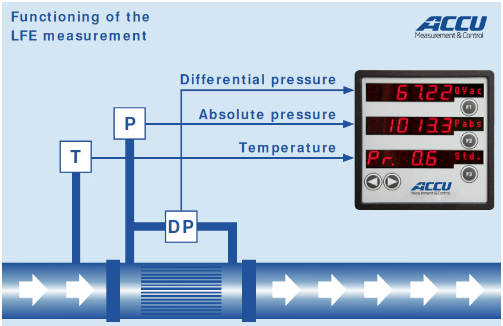

The ACU10F laminar flow differential pressure flowmeter uses differential pressure, absolute pressure, and temperature sensors to measure and compensate for the flow rate, pressure, and temperature of the gas, measuring the volumetric flow rate of the gas under standard conditions (e.g., 1ATM@25℃).

It can measure 4 parameters: mass flow rate, volumetric flow rate, temperature, and absolute pressure. Cumulative flow rate is optional and can be displayed simultaneously on the dynamic display screen.

II. Laminar and Turbulent Flow

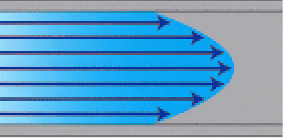

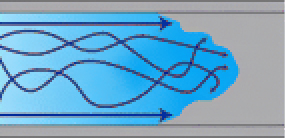

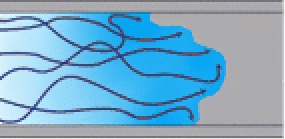

When a fluid (gas or liquid) flows in layers, the flow is described as laminar; when the fluid rotates and mixes across the pipe diameter, the flow is described as turbulent; the flow between the two is described as transitional flow.

Laminar and turbulent flow are two major flow states of fluid motion. The mechanism of turbulent flow is still not fully understood, but differential pressure flow meters based on turbulent flow have been widely used.

Conversely, laminar flow has been thoroughly studied, with a complete mathematical model and descriptive equations. In the laminar state, the fluid velocity and differential pressure are proportional.

Because the differential pressure is linearly related to the flow rate, our laminar flow differential pressure flowmeter has high measurement accuracy over a very wide measurement range.

Laminar Flow Transitional Flow Turbulent Flow III. Laminar Multivariable Measurement Principle

The laminar flow differential pressure flowmeter uses the pressure drop generated inside the laminar flow element to measure the mass flow rate of the fluid. The laminar flow element converts turbulent flow into laminar flow by separating it into a series of thin, parallel channels.

Since the flow is not turbulent, but laminar, the Poiseuille equation can be used to relate the pressure drop to the volumetric flow rate. At a given temperature and pressure, the volumetric flow rate can be converted to mass flow rate using density correction.

For high and low temperature and high pressure operating conditions, real-time measurement of temperature/pressure/differential pressure variables can compensate for the physical properties of the medium to achieve accurate flow measurement.

IV. Measurement Range

① Medium Temperature: -50-300℃

② Pipe Pressure: 0-40MPA

③ Standard Condition Flow Rate: 0-10SCCM~3000SLPM

Note: Larger ranges are available upon request.

V. Interface and Output

① Magnetic buttons and LCD to set flowmeter parameters

② Modbus protocol, optional RS485/RS232 digital interface

③ Multivariable measurement: flow rate/pressure/temperature/differential pressure

④ Zero tracking/accumulation/alarm setting/gas characteristic table/conversion coefficient, etc.

⑤ Analog output provided: 0-5V/4-20mA

Keyword:

Semiconductor and Microelectronics Manufacturing

Get a quote

Note: Please leave your mobile phone number or email address, and our professionals will contact you as soon as possible!