A certain optoelectronic research institute: customized voltage stabilization with 100-millisecond-level response

Project Background: Photoelectric Control and Measurement Needs

Image Source: pexels.com

With the global trend of continuous technological development, photoelectric technology, as a general-purpose technology, is widely used in aerospace, semiconductors, energy, 5G, medical and other fields. China has introduced a number of policies to support the research and development and application of photoelectric technology, and to promote international cooperation and the development of the photoelectric industry.

In the research and production of photoelectric technology, frequent fluid flow control and measurement work is involved, which requires high accuracy and reliability. In the selection of control and measurement instruments, photoelectric enterprises or laboratories will put forward more rigorous and professional quality control requirements according to the working conditions and needs.

Customer Introduction: A domestic photoelectric research institute

Recently, Jingliang Technology received a demand from a domestic photoelectric research institute, and finally purchased customized ACU20PCD dual-valve pressure controllers in multiple batches according to the solution.

This research institute is a national key research institute with a large scale, wide research directions and fields, and has made outstanding achievements in domestic photoelectric research, and has an important position and influence in photoelectric research and development and application.

Working Condition Requirements: Shorten the pneumatic control time and improve the pressure stabilization speed

The technical director of Jingliang Technology first communicated with the contact person of the research institute about the specific working conditions and technical details.

In photoelectric-related operations, the target cavity consists of a suction cup and optical components. The operator injects gas pressure into the optical components to affect the deformation of the optical components through the gas pressure.

Because the optical components have a thin wall thickness, and due to the adjustment of working conditions, the research institute has put forward higher requirements for the control response time of gas pressure, that is, the pressure stabilization time.

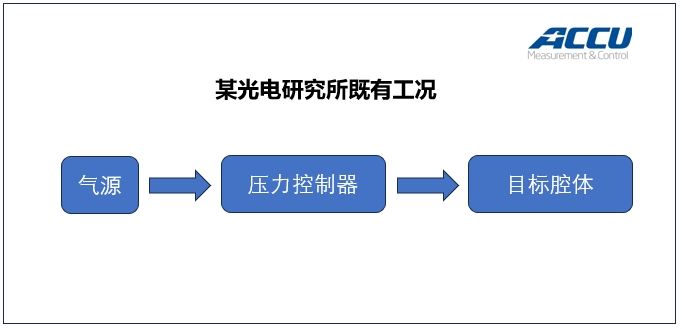

In the existing working conditions, the gas source passes through the pressure controller and directly enters the target cavity, and the pressure stabilization time (pneumatic control time) is relatively long.

Figure: Existing working conditions of a certain photoelectric research institute

The photoelectric research institute put forward the following requirements to the technical director of Jingliang Technology:

1. Shorten the pneumatic control time and improve the pneumatic control accuracy;

2. In terms of pressure control, the pressure range must meet the working conditions requirements;

3. Various accuracies meet the working conditions, and precisely control the thin-walled deformation;

4. Timely and effective after-sales consultation and services can be provided.

Solution: Customized solution based on actual working conditions

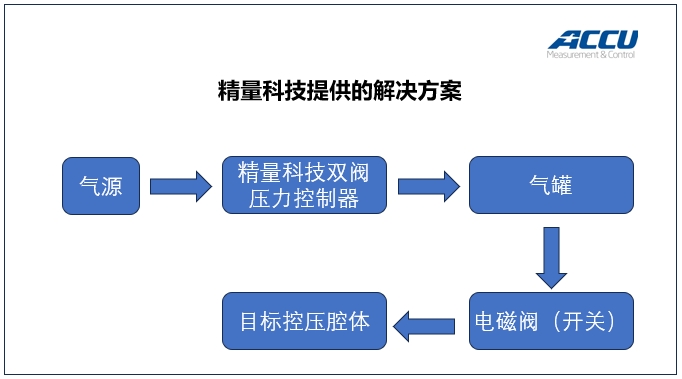

Based on the working conditions and details provided by the photoelectric research institute, the technical director of Jingliang Technology provided a customized solution: In addition to the dual-valve pressure controller, a 2L gas tank and a solenoid valve are added between the gas source and the target pressure control cavity.

Figure: Jingliang Technology solution process

The specific process and effect are as follows: In the initial state, the solenoid valve is closed. First, the Jingliang Technology ACU20PCD dual-valve pressure controller is used to fill the downstream gas tank to about 6 KPa, and after waiting for the prefabricated large cavity pressure to stabilize, the solenoid valve is opened to fill the target pressure control cavity.

At the same time, the dual-valve controller sets the pressure control to 5 KPa, successfully controlling the cavity pressure to 5 KPa within 100 ms.

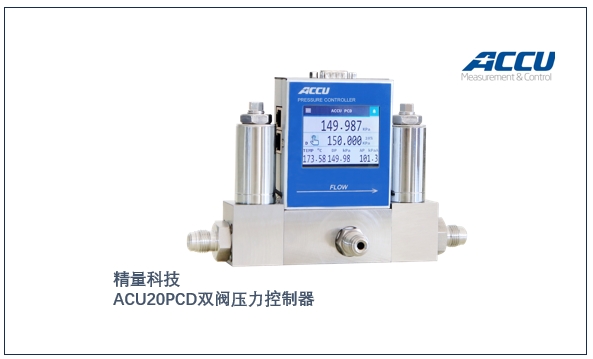

Figure: Customized dual-valve pressure controller used in the solution provided for a certain photoelectric research institute

Project Benefits: Effectively Improve Operational Efficiency

The photoelectric research institute used Jingliang Technology's customized solution to achieve its initial expectations and achieved the following benefits:

1. The pneumatic control time meets the expected requirements, and the pneumatic control accuracy is further improved;

2. Parameters such as the pressure range meet the actual working conditions and meet the precision pneumatic control standards in the operation;

3. Effectively improve operational efficiency and quality;

4. Timely and efficient after-sales technical support escorts the normal operation.

In the cooperation process with the photoelectric research institute, the technical director of Jingliang Technology went deep into the front line, personally understood the working conditions, and provided a complete set of customized solutions based on the working conditions and actual needs, which not only shortened the pneumatic control time but also effectively improved the operational efficiency.

According to the solution provided by Jingliang Technology, the photoelectric research institute purchased the corresponding customized ACU20PCD dual-valve pressure controllers in batches for use in the production operation of photoelectric projects.

Related Products