Application of low-pressure differential mass flow controllers in heat treatment processes

Project Background

This client is a leading enterprise in the heat treatment industry. When facing challenges such as improving equipment automation performance and increasing the domestication rate of equipment, they urgently needed a customized gas mass flow controller/flow meter that meets process requirements. The client proactively contacted Jingliang Technology seeking an efficient solution.

Customer Needs

In a certain heat treatment process, natural gas needs to stably output a maximum flow rate of 30Nm³/h (500L/min) under low inlet pressure (6KPa). The customer originally used a "flow meter + control valve" combination scheme, but the following problems existed:

1. Slow system response speed, difficult to meet rapid adjustment needs;

2. Separation of flow measurement and control leads to reduced accuracy;

3. Large installation space requirements, complex pipeline connections, increasing construction difficulty;

4. High maintenance cost, requiring separate calibration of the flow meter and valve.

5. Simultaneously equipped with analog signals and 485Modbus digital communication, it can be controlled by PLC, computer and other host computers.

Solution

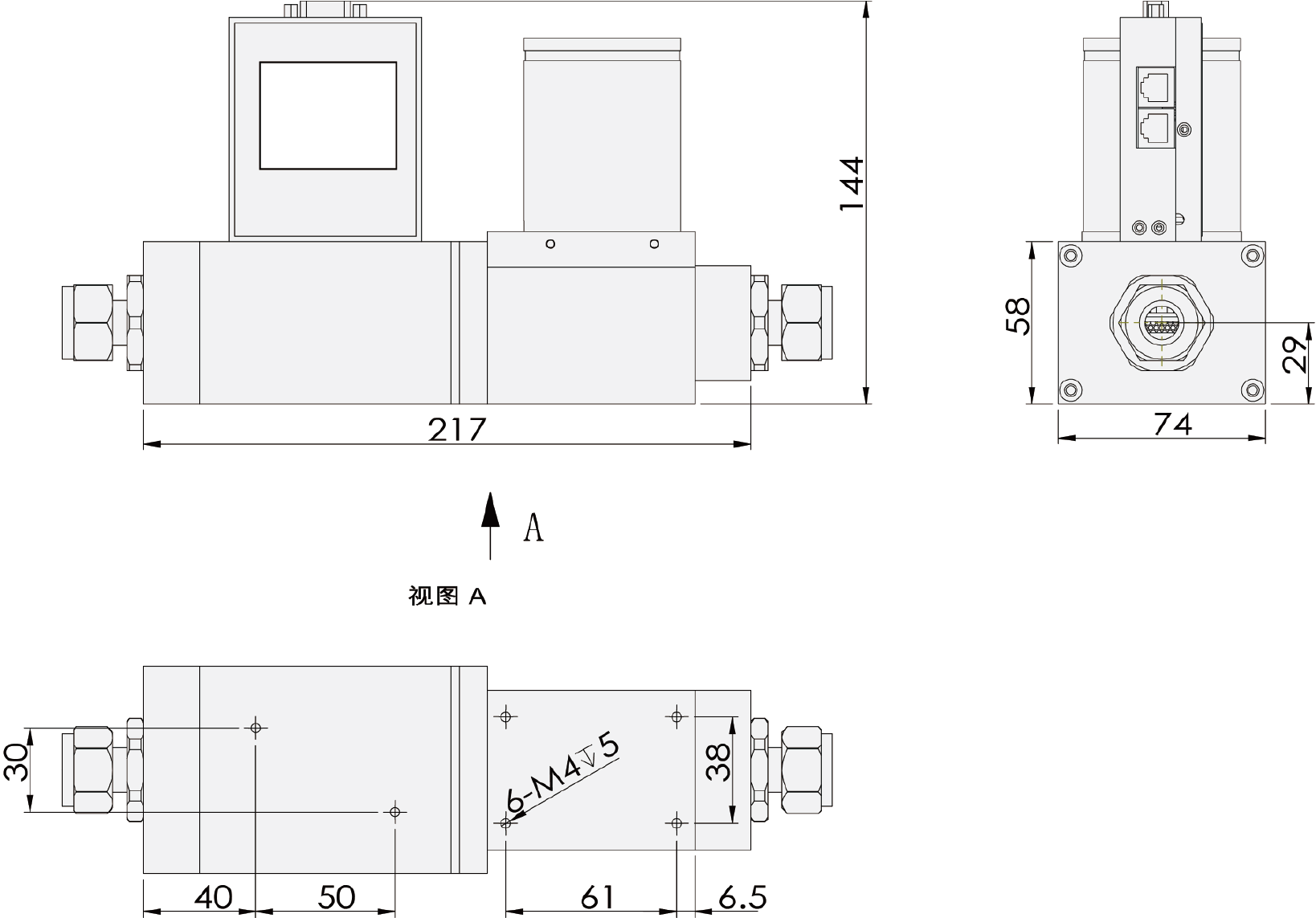

Jingliang Technology In response to customer needs, considering the equipment application scenario, medium characteristics, signal output requirements, especially the core elements of gas working pressure, the ACU20FDR-BC low pressure difference mass flow controller is recommended. The flow meter and valve are integrated in design, through customized valve and built-in PID adjustment function to ensure rapid and stable automated flow control while maintaining low pressure loss; Accuracy can reach ±0.5%FS ; The high-flow electromagnetic valve is equipped to operate stably under low pressure difference, achieving flow control under near atmospheric pressure conditions and shortening the system response time; that is, under a pressure difference of 6Kpa, the natural gas flow can be accurately and stably controlled to reach 30Nm³/h (500L/min), fully meeting the process requirements of outputting a large flow rate under low-pressure conditions in the heat treatment industry.

The basic operating conditions are as follows:

|

Technical Indicators |

Parameter Details |

|---|---|

|

Controlled Medium |

Natural Gas |

|

Measurement Range |

0-30Nm³/h (500L/min) |

|

Pressure |

Inlet pressure approximately 6Kpa, full-scale pressure difference: 6Kpa |

|

Analog Signal |

4-20mA |

|

Communication Method |

RS485 Modbus |

|

Supply Voltage |

24V DC |

|

Interface Type |

RC one-inch threaded interface |

Advantages of the Solution

The ACU20FDR-BC low pressure difference mass flow controller/flow meter solves customer pain points with its core advantages

1. Thermal principle, fast response, high accuracy

2. Tubular flow diversion, not easy to block, easy maintenance

3. Suitable for various low-pressure and high-pressure pipelines, strong compatibility

4. Short preheating time, small zero drift, stable and reliable operation

5. Digital input/output, can use flow computer to control or display flow

ACU20FDR-BC low pressure difference mass flow controller/flow meter is not only suitable for the heat treatment industry, but can also be widely used in industrial manufacturing, petrochemicals, environmental protection, various instrument analysis and other fields, meeting the needs of various scenarios and conditions, providing customers with accurate and stable flow measurement and control solutions, from equipment selection and parameter matching to system integration, providing one-stop measurement and control solutions to help customers achieve intelligent production and maximize energy efficiency.

Previous page

Related Products