A machinery company: High-pressure hydrogen solution promotes the development of the hydrogen production industry

Industry Background: Carbon Peak Drives the Development of the Hydrogen Production Industry

Hydrogen energy has wide applications in transportation, industry, power generation, and construction. In 2021, China became the world's largest hydrogen producer, with an annual hydrogen production capacity of 33 million tons. The China Hydrogen Energy Alliance predicts that by 2030, during the carbon peak period, China's annual hydrogen demand will reach 40 million tons. Hydrogen energy production involves flow measurement and control technology, and gas mass flow meters play a key role in ensuring hydrogen quality.

Company Overview: Supplier of Hydrogen Production Equipment

Hefei [Company Name] is a company mainly engaged in mechanical automation equipment, experimental equipment platforms, and industrial automation systems. Providing hydrogen production equipment for the hydrogen production industry is one of its main businesses.

Working Condition Requirements: Hydrogen Production Equipment under High-Pressure Conditions

In March 2024, Hefei [Company Name], while researching and developing hydrogen production equipment, needed to purchase a batch of gas mass flow controllers/meters and contacted [Company Name], emphasizing whether they could provide gas measurement and control instruments for high-pressure hydrogen equipment.

After detailed communication, Hefei [Company Name] compiled a detailed list of operating parameters:

Measurement and Control Medium: Hydrogen

Range: 0-500 SCCM

Pressure Resistance: 40 MPa

Differential Pressure: 2-3 MPa

Input and Output Signals: 4-20 mA

Communication Method: RS485

Supply Voltage: 24V dc

Connector: 1/4 inch compression fitting

Solution: Accurate Product Recommendation Based on Medium Characteristics and Operating Conditions

Due to the low density and high flammability of hydrogen, the temperature range of its measurement and control is relatively wide. The measurement and control accuracy of the selected instrument should not be affected by pressure and temperature. [Company Name] comprehensively considered the characteristics and operating conditions of hydrogen and recommended the ACU20FD-LC high-precision mass flow controller/meter to Hefei [Company Name].

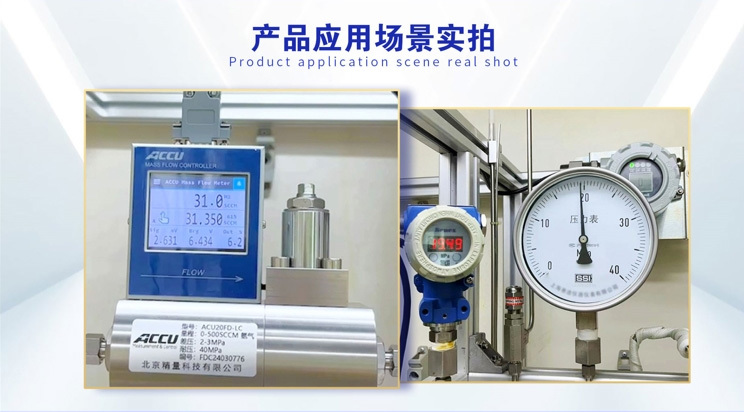

Figure: ACU20FD-LC high-precision mass flow controller/meter used in the high-pressure hydrogenation equipment scheme

This measurement and control instrument uses a thermal principle, has a fast response, is not affected by temperature and pressure, has a measurement and control accuracy of ±0.5% F.S, and a repeatability of ±0.2% F.S. The core parameters meet the hydrogen measurement and control range standards.

[Company Name] customized the pressure resistance and pressure difference according to the customer's operating conditions, so that the instrument's pressure resistance reaches 40 MPa and the pressure difference is 2-3 MPa.

Hefei [Company Name] approved [Company Name]'s solution and purchased a batch of [Company Name] ACU20FD-LC high-precision mass flow controllers/meters for use in high-pressure hydrogenation equipment.

Project Benefits: Increased Orders, Improved Market Share

After several months of operation, the customer feedback indicated that the [Company Name] ACU20FD-LC high-precision mass flow controller/meter has stable flow control and reliable accuracy in high-pressure hydrogenation equipment, and the software is simple and easy to use, with high satisfaction.

Figure: On-site photos of the ACU20FD-LC mass flow controller/meter in a high-pressure hydrogenation device

This solution brings the customer the following two benefits:

1. Achieves high pressure resistance performance for the device, meeting market demand

The high pressure resistance performance required by the hydrogen production industry is quite special. [Company Name]'s enabling of high-pressure functionality for Hefei [Company Name]'s hydrogenation equipment helps increase orders and improve market share.

2. Ensures stable production operation

The ACU20FD-LC uses a customized method, suitable for high-pressure environments, and can achieve stable control at various pressure stages to ensure stable production operation.

Using [Company Name]'s measurement and control solution, Hefei [Company Name] solved the problem of flow control in high-pressure hydrogen production. [Company Name], with its high-precision products and professional services, empowers the wide application of future hydrogen energy.

With the continuous development of the hydrogen production industry, [Company Name] will provide more advanced and precise solutions, continuously helping customers improve their competitiveness and jointly move towards a green and low-carbon future.

Related Products