Flow meters and flow controllers suitable for hydrogen

Hydrogen is an element that forms a simple substance. At normal temperature and pressure, the density of hydrogen is 0.089g/L (101.325kpa, 0°C), which is only 1/14 of that of air, and it is the gas with the smallest known density in the world. With the increasing emphasis on clean energy, the application of hydrogen is becoming more and more extensive, and in practical applications, it is often necessary to measure or control the amount of hydrogen.

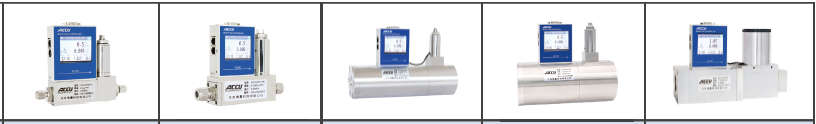

Mass flow meters (MFM) or mass flow controllers (MFC) are well-suited for hydrogen's characteristics due to their high accuracy and ability to implement electrical automation control. The following mass flow meter and flow controller have been widely used in hydrogen flow measurement and control, and have high airtightness, which can effectively avoid the risk of hydrogen leakage. In some special applications, explosion-proof boxes can also be added to meet design requirements.

Range: 2SCCM~6000SLM

Control Range: Controller valve control range 50:1, flow measurement range ratio 100:1

Accuracy: <±0.5%F.S

Linearity: <±0.5%F.S

Repeatability : ≤±0.2%F.S

Response time : <0.2s <0.1s

Temperature coefficient: ±0.025%F.S/℃

Working pressure difference: 0.1~0.5Mpa (low pressure loss can be customized), flowmeter working pressure drop: <0.01Mpa

Maximum pressure resistance: 3MPa/10MPa /20MPa/40MPa (Please communicate for customization if greater than 10MPa)

Leakage rate: 1×10 SCCSHe

Base material : Stainless steel

Connector : φ8,φ10,φ12,ferrule, VCR, flange installation, etc.

Sealing material : Fluorine rubber, nitrile rubber, etc.

Shell protection level : IP40 / IP65

Installation position : Horizontal installation (some applications can be installed in any position)

Electrical connection : DB9 female, RJ11, 5.5×2.1 power quick connector; (can be matched according to customer needs)

Display status : With LCD display, without LCD display

Digital quantity : RS232/485, Modbus protocol, Profibus-DP protocol, DeviceNet protocol, etc.

Analog quantity : 0~5V、4-20mA、1~5V

Power supply : 24VDC、±15VDC、220V

Previous page

Next page

Previous page:

Next page:

Related Products