A certain experimental instrument company: leveraging customized capabilities to conquer harsh working conditions

Image source: pexels

Customer Introduction

A certain experimental instrument company, which develops various high-end experimental equipment and systems for universities, laboratories, and scientific research enterprises. The equipment and systems are mainly used in geotechnical engineering, materials science research, and scientific research teaching.

Operating Conditions Requirements

This experimental instrument company needs to integrate an experimental device for a customer, which requires a gas pressure control function. If a pressure controller is configured, the control pressure must be 15 MPa high pressure, 200 L/min high flow rate, and other partial operating condition requirements are also proposed.

The experimental instrument company stated that they consulted several domestic and foreign measurement and control companies, but none could generally meet these operating condition requirements. The company staff contacted ACCU, hoping to solve this problem.

Solution

The customer clearly only needs a pressure controller, but has not yet found a product that meets the operating conditions on the market. In order to accurately recommend products, ACCU staff communicated in depth with the customer's needs, and learned in detail about the equipment's use, medium, signal output, gas source pressure, and other information. At the same time, they promoted the customer to collect operating condition data and communicated with internal technology.

The customer finally sorted out the operating conditions and conveyed them to ACCU. The basic operating conditions are as follows:

Controlled Medium: Air

Pressure Control Range: 0~10MPa, gauge pressure

Control Ratio: 50:1

Gas Source Pressure: 15MPa

Cavity Volume: 105L

Corresponding Maximum Flow Rate: 200L/min

Signal: 4~20Ma

Communication Method: RS485

Connector: External thread M24*1.5 24° cone

The valve of the pressure controller is a core component, and different valves are configured for different application scenarios. After understanding, the customer also requires the controller to have pressure stabilization and pressure relief functions, and to support high-temperature operating conditions. To achieve this function, a double valve needs to be installed on the pressure regulator, and a split control valve must be used to meet the operating condition requirements.

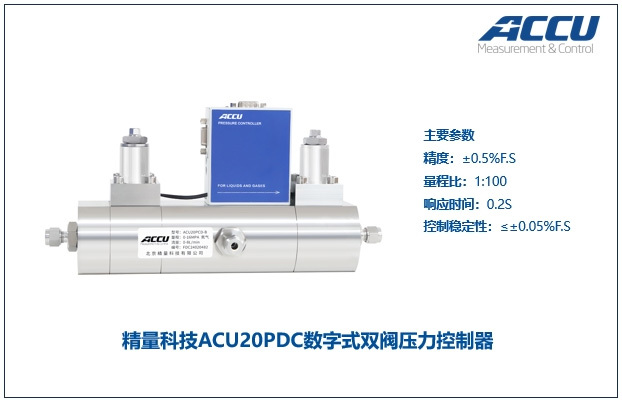

Because this operating condition is relatively special, ACCU staff proposed a customized solution: based on the general model of ACCU ACU20PCD digital dual-valve pressure controller, add a split control valve, increase the maximum flow rate, and change the connector type, etc.

Figure: ACU20PDC digital dual-valve pressure controller

After completing the solution, the customized product was tested under operating conditions, and the results met the customer's actual needs, and the delivery was successfully completed.

Project Benefits

The customized solution proposed by ACCU staff helped the customer complete the project delivery and achieved good results:

1. Successful high-quality delivery, winning market trust

With the cooperation of ACCU, the experimental instrument company overcame complex operating condition requirements and successfully completed the project delivery with high quality, winning market trust.

2. Shorten delivery time, efficiently complete the project

ACCU, with its perfect service level, worked with the customer to carefully sort out the operating conditions and developed a customized solution, thereby helping the customer shorten the delivery time.

3. Extra-long after-sales service, ensuring peace of mind

The product provides extra-long warranty service and technical support during use to ensure normal operation and efficient operation of the equipment.

In this project, ACCU fully demonstrated its customization capabilities and successfully met the demanding operating condition requirements. Through close cooperation and communication, we not only provided customers with satisfactory solutions but also accumulated valuable experience for the company itself.

In the future, ACCU will continue to cultivate the experimental instrument field, using innovative technology, high-quality products, and perfect services to help more customers achieve high-quality development.

Related Products