ACU20FE Ultra-Low-Temperature (-196°C) Coriolis Mass Flow Meter

Project Background

Over the past decade, as liquid nitrogen technology has deeply penetrated fields such as aerospace, biomedicine, and high-end manufacturing, precise sample storage and process control under ultra-low-temperature conditions have become core industry demands. However, traditional monitoring methods have long been constrained by the following bottlenecks:

Conventional mass flow meters only support a temperature range of -40°C to +80°C, which is insufficient to ensure stable operation at the boiling point of liquid nitrogen (-196°C). Moreover, when some flow meters are exposed to such extreme environmental conditions for extended periods, the drastic temperature differences between the inside and outside of the storage tank can easily lead to a significant drop in measurement accuracy or even data drift, ultimately causing the meter to fail. This results in inaccurate measurements, production disruptions, and substantial financial losses.

Solution

To address the challenges posed by the above-mentioned harsh operating conditions, ACCU (Beijing AccuFlow Technology), leveraging more than a decade of accumulated expertise in fluid measurement and control technology, offers a solution: the ACU20FEH-LM small-flow Coriolis mass flowmeter.

This independently developed and produced mass flow meter utilizes the Coriolis principle, enabling direct measurement of mass flow without being affected by other fluid properties. Unlike other large-scale Coriolis flow meters, this Coriolis mass flow meter excels in the precise measurement and control of low-flow applications, and has been successfully integrated into various fields, including scientific research experiments and industrial production.

As the demand for flow measurement and control of ultra-low-temperature media continues to grow, we have optimized and expanded the performance of the ACU20FEH-LM Coriolis mass flowmeter. Now capable of withstanding temperatures as low as -196°C, this advanced instrument, combined with a remote control system, enables precise measurement of ultra-cold fluids—providing continuous or intermittent outputs of either instantaneous or cumulative flow rates.

Core Highlights

1. High Precision and High Repeatability

The ACU20FE Micro Coriolis Mass Flow Meter delivers highly accurate measurements with exceptional resolution, capable of detecting even the tiniest flow rates—as low as 0.05 g/h. Its accuracy (precision) can reach 0.25% to 0.5% of full scale, while liquid measurement accuracy is up to ±0.25% of full scale. With a maximum measurement range ratio of up to 100:1, this meter effectively minimizes measurement errors and boasts outstanding repeatability, providing users with stable and reliable flow data.

2. Corrosion-resistant

The ACU20F micro Coriolis mass flow meter maintains long-term performance stability even when handling corrosive media, remaining unaffected by media erosion, significantly extending its service life and effectively reducing measurement deviations caused by contamination. Its outstanding corrosion and fouling resistance make it widely applicable in industrial settings such as chemical processing, petroleum refining, semiconductor manufacturing, pharmaceuticals, and various instrument analysis applications that involve corrosive or contaminated fluids.

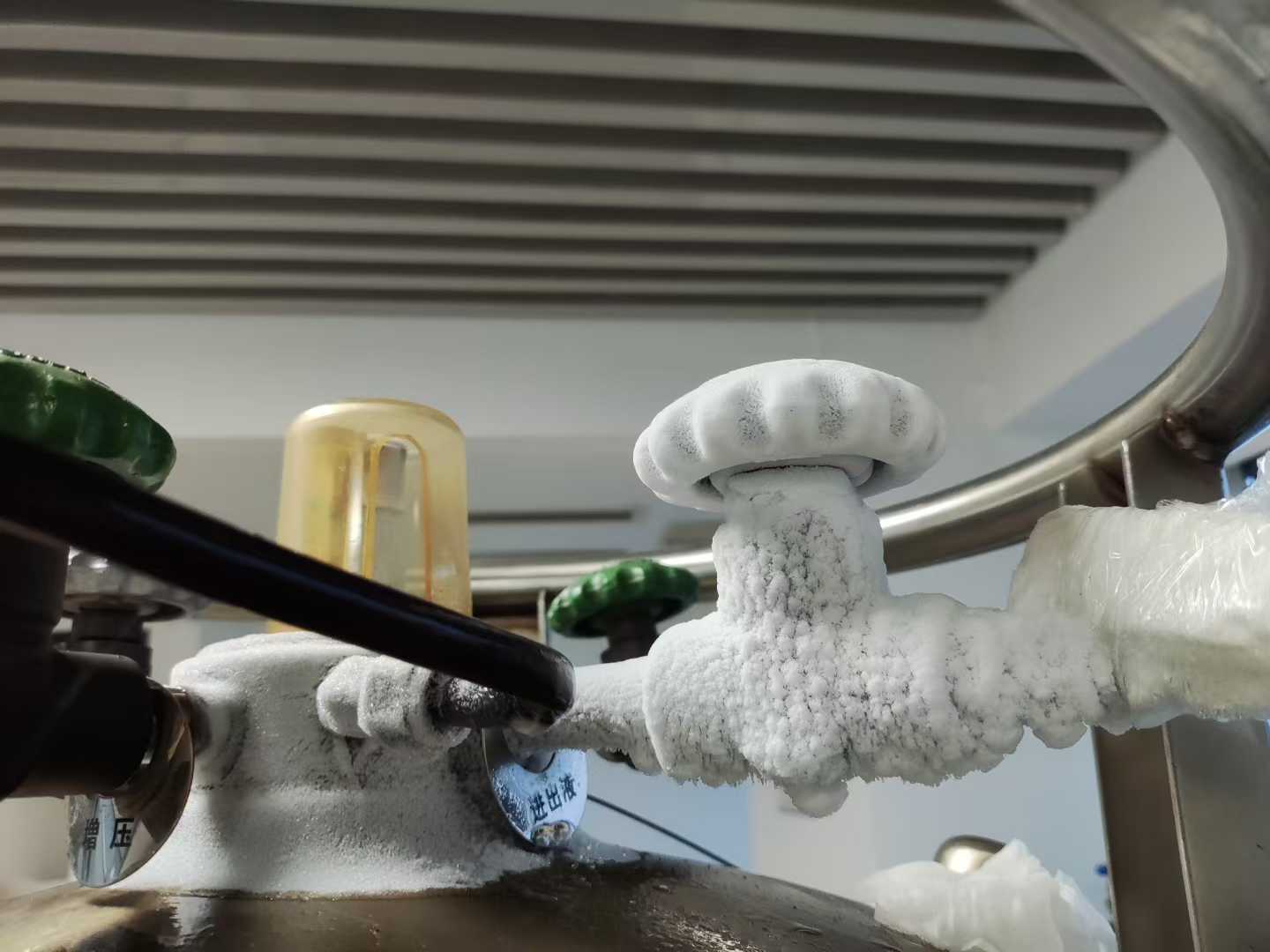

3. Low-Temperature Resistance

The ACU20FE micro Coriolis mass flow meter features cold-temperature resistance, enabling stable operation even at extremely low temperatures as low as -196°C, while continuously delivering precise and reliable flow data to help users achieve process control and production optimization.

4. Wide Measurement Range

This flow meter covers a wide range, from microflows to medium- and high-capacity flows, specifically including:

● Low range: 0 to (20 g/h ~ 50 kg/h)

● Medium range: 0 to (50 kg/h ~ 100 kg/h)

● Large range: 0 to (100 kg/h ~ 300 kg/h)

● Ultra-wide range: 0 ~ (300 kg/h ~ 1000 kg/h)

It can be applied to high-precision measurement requirements under various flow conditions.

5. Excellent Adaptability

The Coriolis mass flow controller/flowmeter is unaffected by the physical properties of the fluid, making it suitable for a wide range of fluid applications. It is ideal for various gases (such as air, nitrogen, oxygen, and more) and liquid media—including water, oils, organic solvents, and more—demonstrating excellent versatility and stability.

6. Communication Signals

This flowmeter is specifically designed to closely meet the demands of online monitoring and control in industrial settings, supporting a variety of standard signals—including analog signals (4–20mA/0–5V) and digital communication interfaces (such as RS232/RS485, Profibus-DP, DeviceNET, and other protocols). It enables high-precision data acquisition and flow control remotely, allowing users to choose based on their specific application requirements and environmental conditions.

From gaining insights into industry challenges, to developing cutting-edge technology solutions, and finally delivering tangible value in real-world applications, ACCU has consistently driven innovation and remained customer-focused. By providing high-precision, high-performance solutions, we empower our clients to achieve safe and efficient fluid measurement and control. The technological strengths of the ACU20FE micro Coriolis mass flow meter—along with its advanced capabilities for ultra-low temperature liquid nitrogen measurement and control—demonstrate not only our expertise in precision measurement and cryogenic engineering, but also our unwavering commitment to continuously delivering exceptional value to our customers.

If you're facing similar measurement and control challenges, feel free to contact us for customized solutions and technical consultations.

Previous page

Related Products