Automotive Nozzle Flow Performance Test Platform Based on Negative Pressure Method - Supporting Multi-Vacuum Flow Evaluation and Achieving Accurate Determination of Nozzle Ventilation Performance

Project Background

A certain company specializes in manufacturing crankcase ventilation valves for car engines. The main function of this valve is to regulate the gas flow in the crankcase to ensure smooth engine operation. To determine whether the performance of such valves meets the standards, it is necessary to simulate their actual working conditions, that is, to test whether the gas flow through the valve meets the specified flow standard under different vacuum suction conditions.

The original testing equipment was manual, with slow response speeds for pressure control and flow measurement, low accuracy, poor repeatability, and low efficiency requiring repeated tests. Therefore, the company's technicians contacted AccuFlow Technology to seek a high-precision, high-stability, and fast-response automated pressure control and flow measurement solution.

Our independently developed pressure controller and flow meter have good accuracy, stability, and an intelligent and efficient operating method. They can precisely match the customer's required testing methods, significantly improve testing efficiency, and provide reliable and efficient assurance for the customer's quality control.

Customer Needs

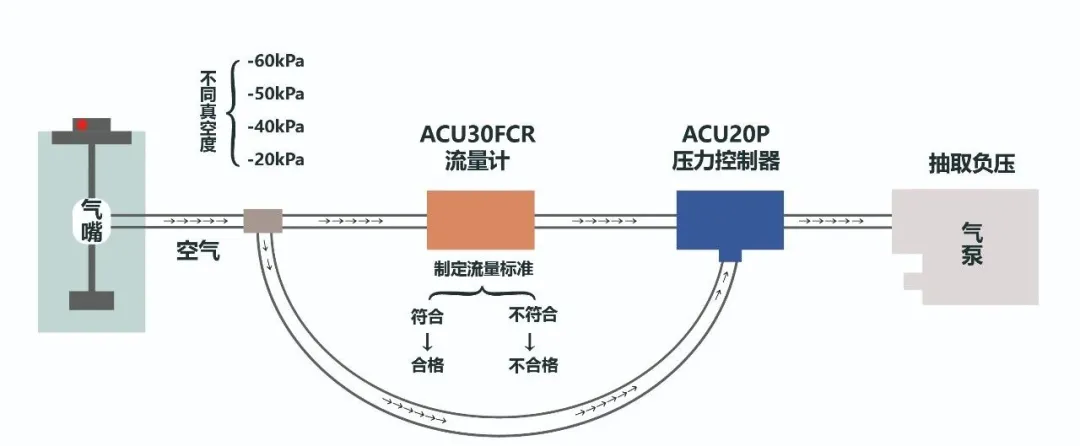

1, It is necessary to measure the flow data of the valve under different negative pressure conditions such as -60kPa, -50kPa, -40kPa, and -20kPa. These vacuum pressure values cover the typical environments that this valve may encounter in actual applications. Flow data is collected under these pressure conditions, The measured flow data is compared and analyzed with the specified flow standard values to accurately determine whether the valve meets the design requirements. Ultimately, the pass rate of this valve product can be effectively detected , providing reliable test data for subsequent batch production acceptance, performance screening, and other processes.

2. The dynamic stability and response speed of the existing equipment's absolute pressure control do not meet the standards, resulting in poor repeatability of the test data and affecting efficiency. Specifically: When the vacuum changes from -60kPa to -50kPa , the equipment takes a long time to stabilize at the target pressure, and the pressure fluctuation is too large after stabilization; at the same time, the response delay of the flow sensor is obvious when the pressure changes, and the deviation between the three measurements of the same valve under the same vacuum is large. This forces the inspectors to perform multiple repeated measurements to verify the reliability of the data, greatly increasing the testing time, seriously affecting work efficiency, and may also lead to misjudgment due to data uncertainty, causing subsequent quality risks.

3. If a similar foreign solution is adopted, it will not only affect the progress of the production plan but also increase the company's operating costs. Choosing to cooperate with our company ensures timely and efficient communication, guarantees the supply cycle of related equipment, and greatly reduces procurement and maintenance costs, greatly optimizing the cost structure.

Solution

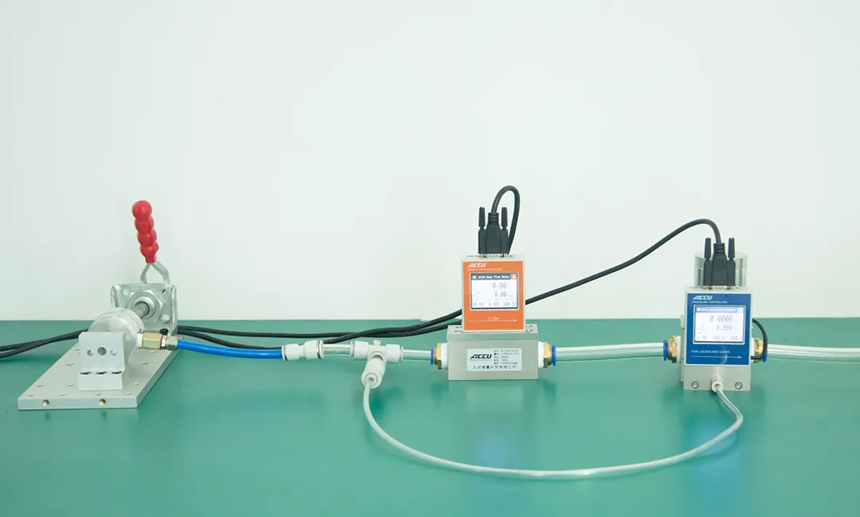

ACU20P Pressure Controller + ACU30FCR Flow Meter

AccuFlow Technology In response to customer needs, we propose a solution centered on ACU10P/ACU20P pressure controller and ACU30FCR flow meter . Through customized structural design and specific parameter configuration, this solution forms a highly efficient automated closed-loop detection system.

Specifically, this solution can achieve a complete automated closed-loop process: "Issue test instructions under different vacuum pressures → rapid pressure stabilization (fluctuation ≤ ±0.2%) → real-time flow acquisition → automatic comparison with standard values, determination of pass rate" . ACU10P/ACU20P pressure controller With its excellent performance, it can greatly shorten the response time during vacuum pressure changes, ensuring rapid pressure stabilization from the source; ACU30FCR flow meter It accurately captures the changes in the gas flow of the valve under different vacuum pressures with 0.5-level measurement accuracy and millisecond-level response time, ensuring data real-time and reliability.

This solution not only provides customers with stable and accurate test data support but also fully meets the needs of detecting the valve pass rate under the design standard of specific vacuum pressure corresponding to specific flow . At the same time, this solution further shortens the detection cycle , providing customers with a practical solution for cost reduction and efficiency improvement.

ACU20P Pressure Controller + ACU30FCR Flow Meter Process Principle Diagram

Its basic operating conditions are as follows:

Parameter Category | ACU10P/ACU20P Pressure Controller | ACU30FCR Flow Meter |

|---|---|---|

Control Medium | Air | Air |

Measurement Range | -100 kPa~0 (Gauge Pressure) | 0-250 SLM |

Accuracy | ±(0.2~0.5)% F.S | ±0.5% F.S |

Operating Flow/Pressure | 100 SLM | Vacuum |

Response Time | <0.2 s | 50ms |

Operating Temperature | -10~+70℃ | -10~60 ℃ |

Communication Method | Modbus protocol (RS485/232) | Modbus protocol (RS485/232) |

Supply Voltage | ±15 V dc 24V dc | ±15 V dc 24V dc |

ACU10P/ACU20P pressure controller Widely used, not only applicable to valve detection, but also to gas and liquid phase analysis equipment, pressure control in semiconductor processes, gas pressure protection control in extrusion molding, pressure control in high-pressure reactors/reaction vessels, pressure control in leak detection, flow detection, and other scenarios.

AccuFlow Technology Dedicated to providing customers with precise and reliable fluid measurement and control solutions. From equipment selection and parameter matching to system integration, we provide customized services tailored to your needs, helping you achieve intelligent production and maximize energy efficiency.

Related Products