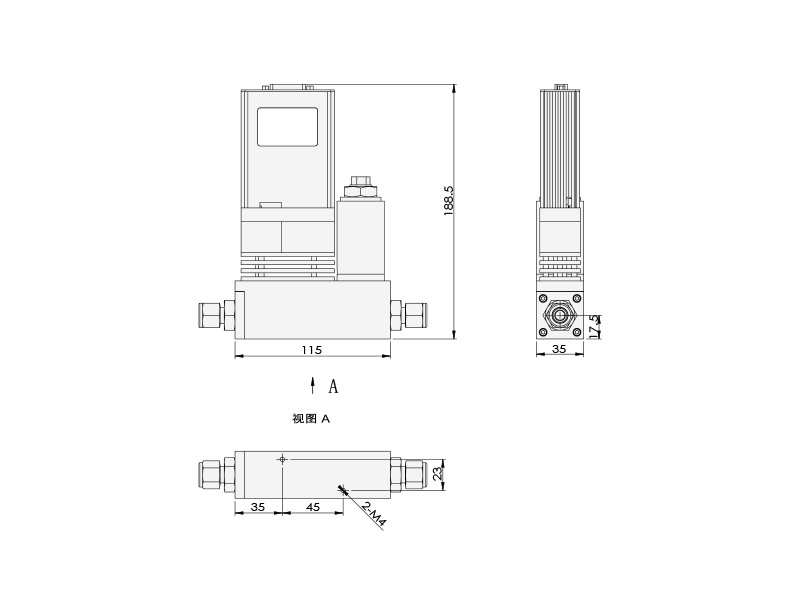

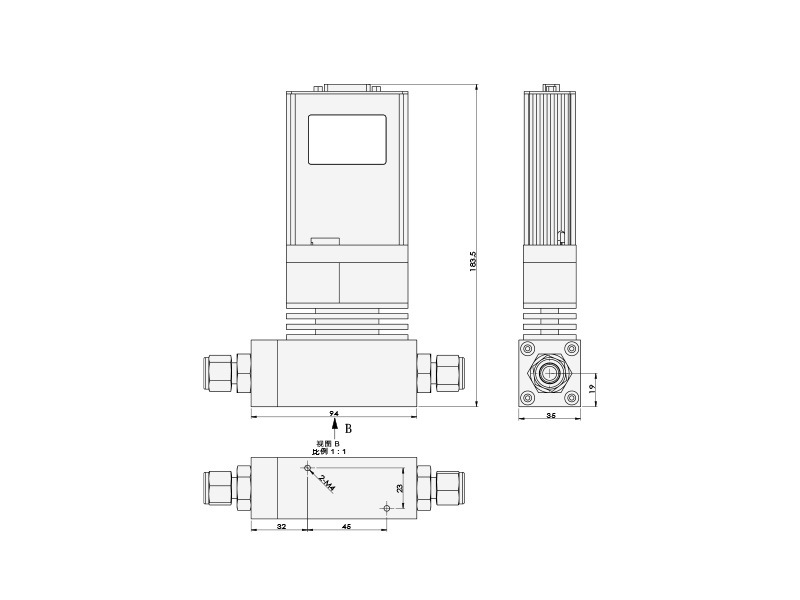

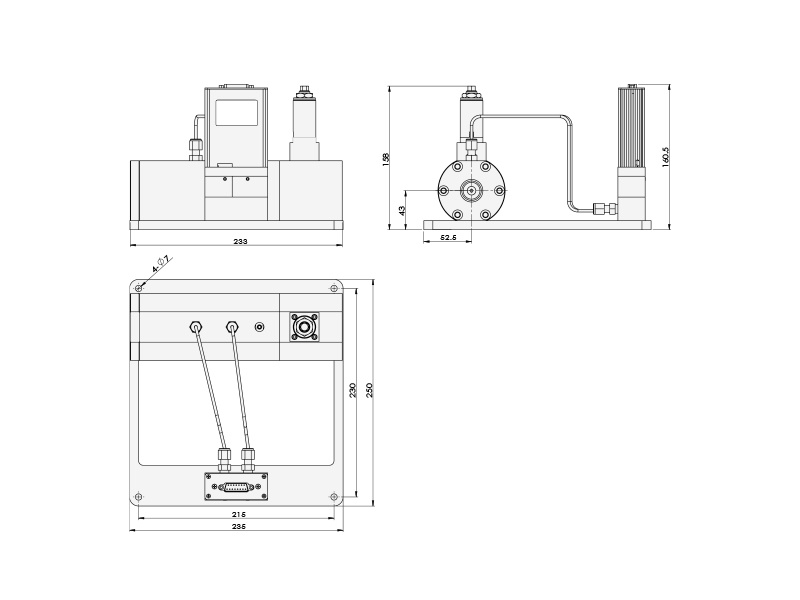

Integrated Dimension Drawing for ACU10FCH-LC

Product Center

ACU10FCH

Category:

Product attachment:

Product Description

- Product Description

-

I. Product Overview

◆ Quickly and accurately measures the volumetric or mass flow rate of process gases, liquids, or vapors

◆ Employs custom high-speed proportional control valves for precise regulation of media volumetric or mass flow rates.

◆ When measuring liquids, the uniquely designed vent hole allows air to be easily released.

◆ Integrated multi-function digital display allows users to control setpoints and PID valve adjustments effortlessly—simply by operating the on-screen buttons—while also providing flexible analog input/output capabilities and RS-485 digital communication.

◆ No movable components or heating elements inside; passes vibration tests and is insensitive to installation orientation.

◆ Utilizing internally compensated laminar flow differential pressure technology ensures that the fluid maintains laminar flow even at high flow rates.

◆Offering comprehensive user support, including technical consultations, fast equipment calibration services, and a conditional lifetime warranty.

II. Product Applications

The ACU10FCH series of high-temperature mass flow meters/controllers are widely used across various industries, including process manufacturing, food analysis, analytical testing, and metrology.

Multi-variable measurement and a 50:1 adjustable range allow a single ACU10FCH high-temperature mass flow meter/controller to replace the functionality of multiple devices. With 1% accuracy, 1% repeatability, and a control response time of less than 200 milliseconds, it ensures reliable operation for process gases, liquids, and vapors.

3. Technical Specifications

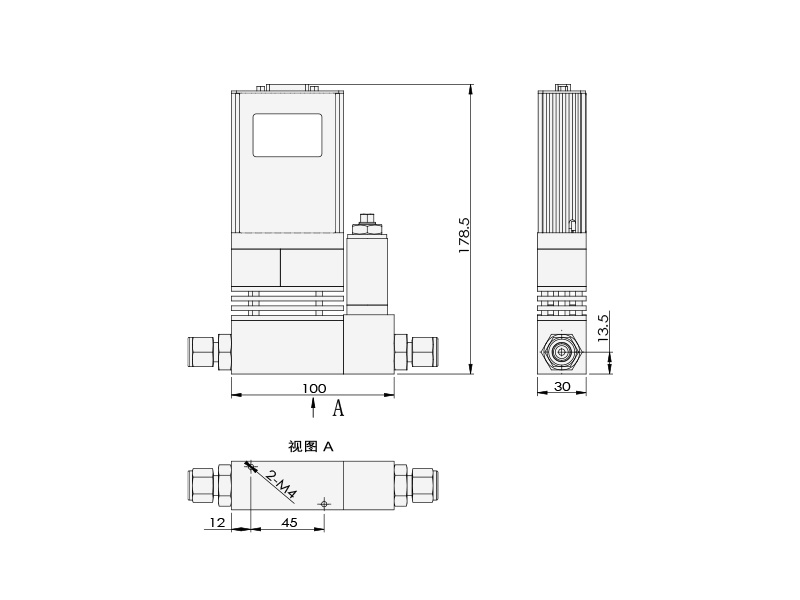

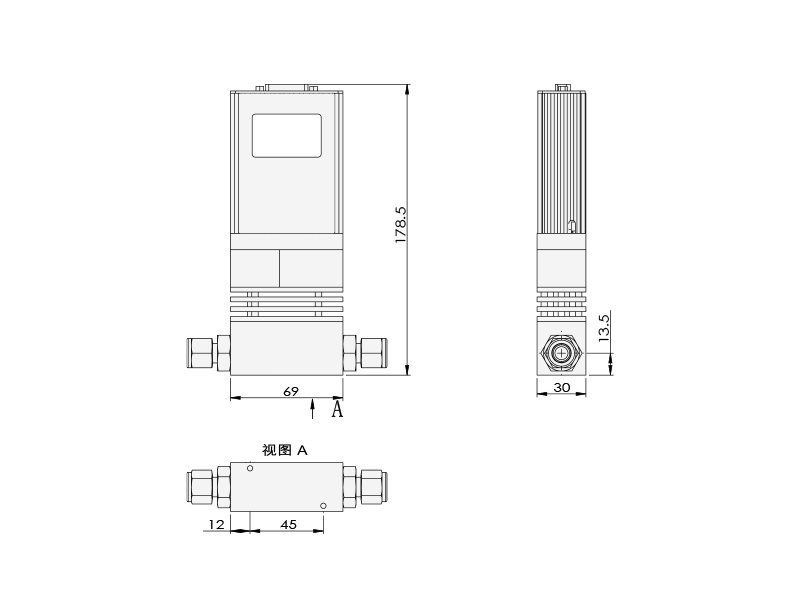

Series ACU10FCH Model LC LM MC MM BC BM Measurement range Gases: 0–(2, 5, 10…1000) SCCM, 0–(1, 5, 10…30) SLM Gas: 0–(30, 40, 50...300) SLM Gas: 0–(300, 400, 500...3000) SLM Liquid: 0–(2, 5, 10...500) SCCM Liquids: 0–(500, 600…1000) SCCM, 0–(1, 2, 3…10) SLM Liquid: 0-(1, 2, 30...10) SLM Steam: 0–(2, 5, 10...1000) SCCM, 0–(1, 2, 3...10) SLM 0 - (10, 20, 30...100) SLM 0 - (100, 150, 200...500) SLM Accuracy ±1.0% of F.S. Repetitiveness ±1% of F.S. Zero-point drift & Full-scale drift 0.02% F.S./°C/Atm Work differential pressure 0.1–0.5 MPa (specified upon order) Measurement range ratio 50:1 100:1 50:1 100:1 50:1 100:1 Typical Response Time 200 milliseconds (adjustable) Analog quantity 0–5V, 4–20mA Digital quantity RS232/485, MODBUS Protocol Power supply 24VDC Operating temperature +10 to +50°C Work pressure drop <0.01 MPa Work stress <1 MPa Electrical connection DB15 port Protection Level IP40 Leak rate 1 × 10⁻⁹ Pa·m³/s Valve Valve remains closed / Valve remains closed / Valve remains closed / Base material Stainless steel Sealing material Fluororubber, nitrile rubber, EPDM, perfluoroether Surface Thread G3/8 internal thread G1/2 internal thread Connector Crimpers, towers, quick-connect fittings, VCRs, flanges, and more 4. Product Dimension Diagram

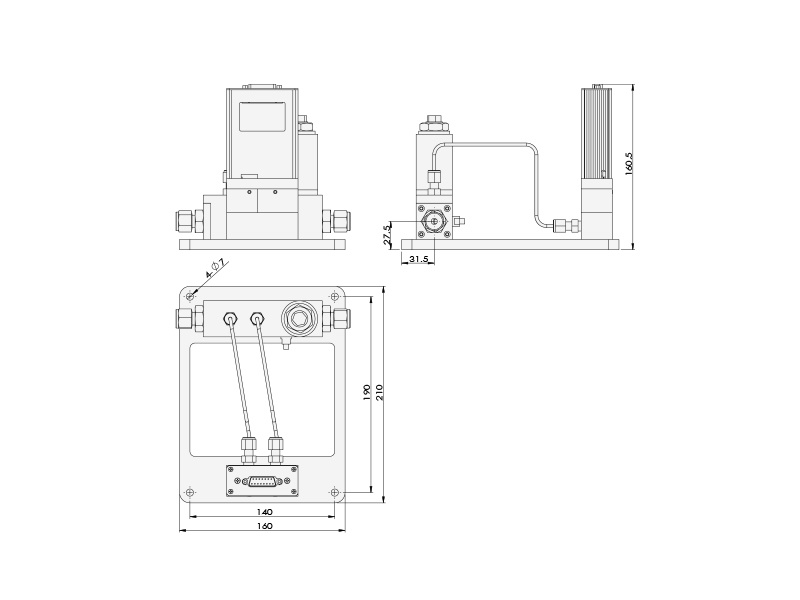

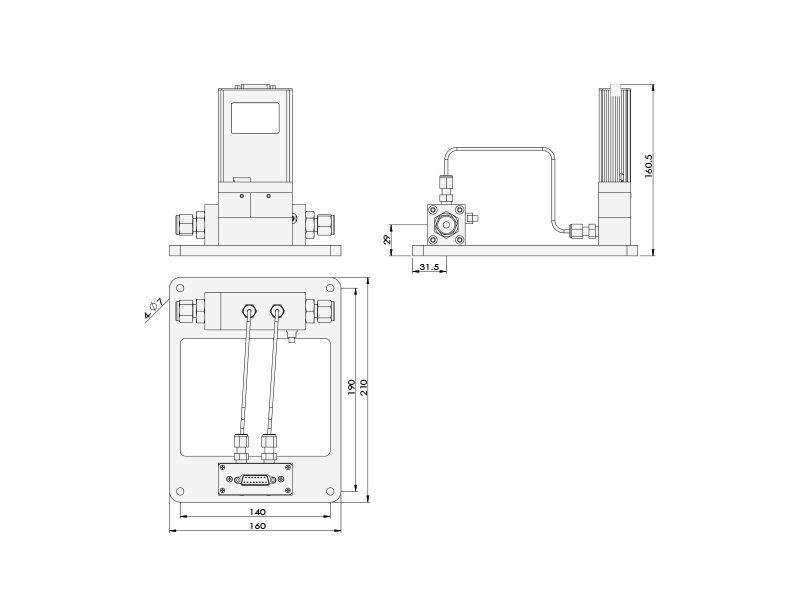

5. High-Temperature Steam Flow Controller

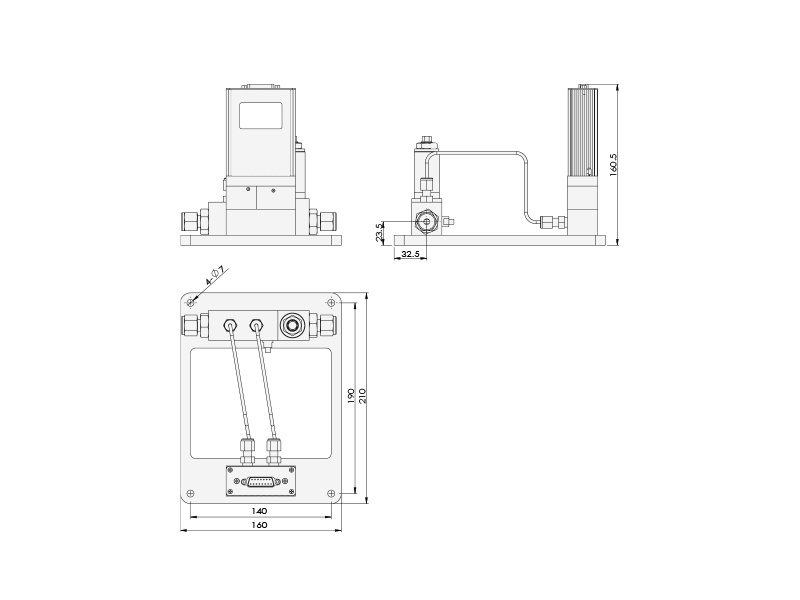

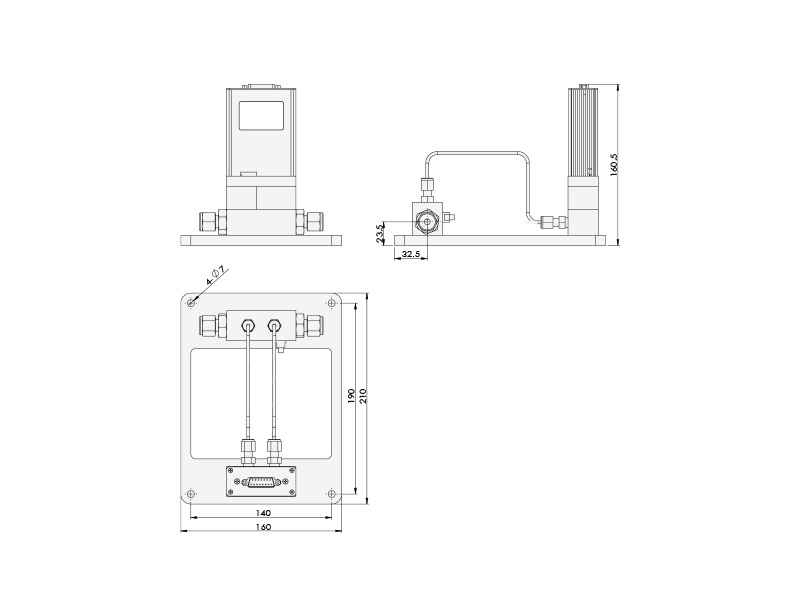

When the measured medium and flow rate differ, the product's appearance and dimensions may vary. For example, the medium-range high-temperature steam flow controller shown in the image below—please consult based on your actual operating conditions.

(High-Temperature Steam Flow Controller)

6. Optional accompanying measurement and control software (additional charges apply)

Quality Flow Measurement and Control System V5.0

Keyword:

Semiconductor and Microelectronics Manufacturing

Get a quote

Note: Please leave your mobile phone number or email address, and our professionals will contact you as soon as possible!