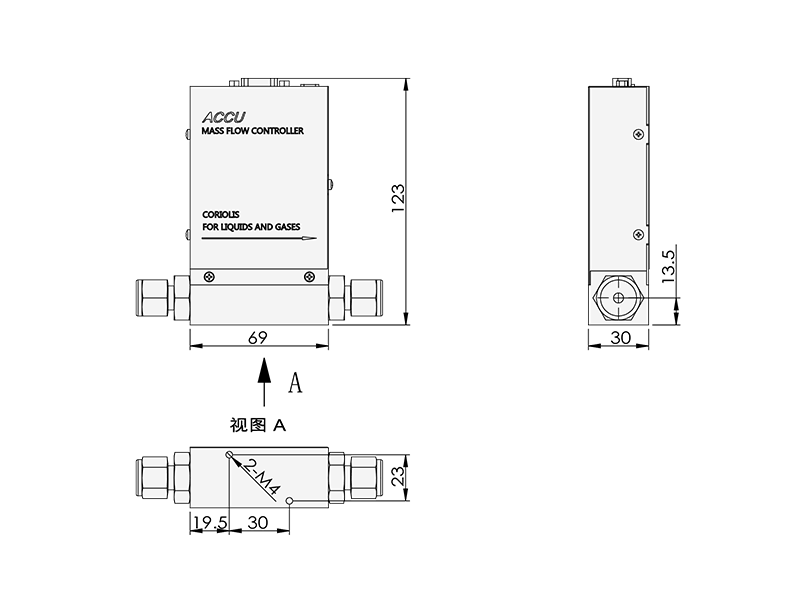

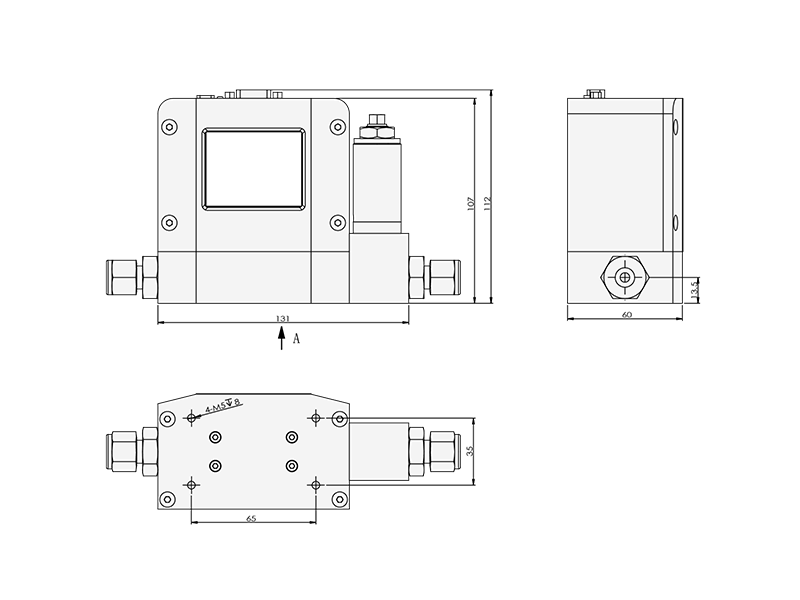

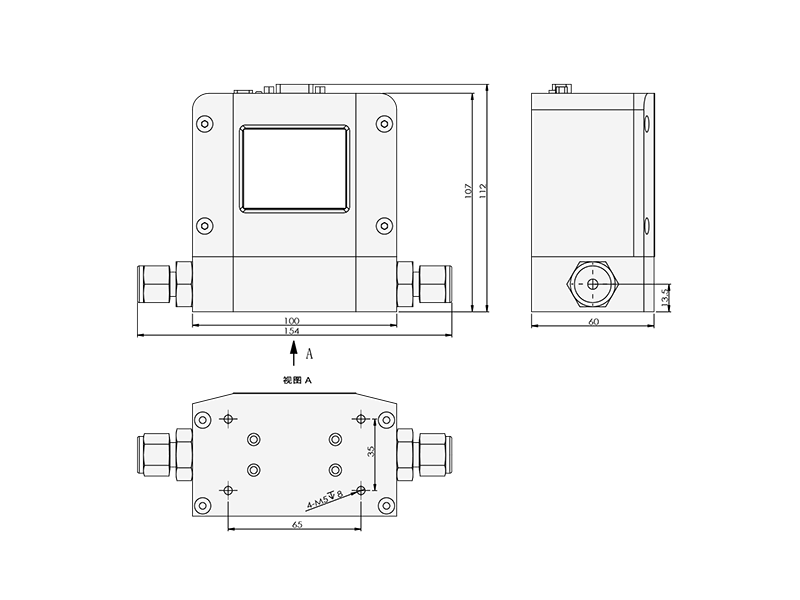

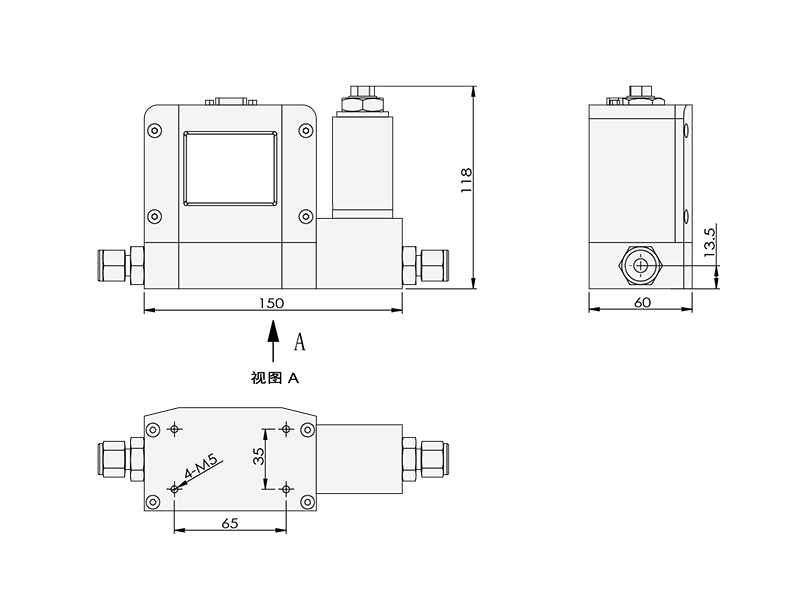

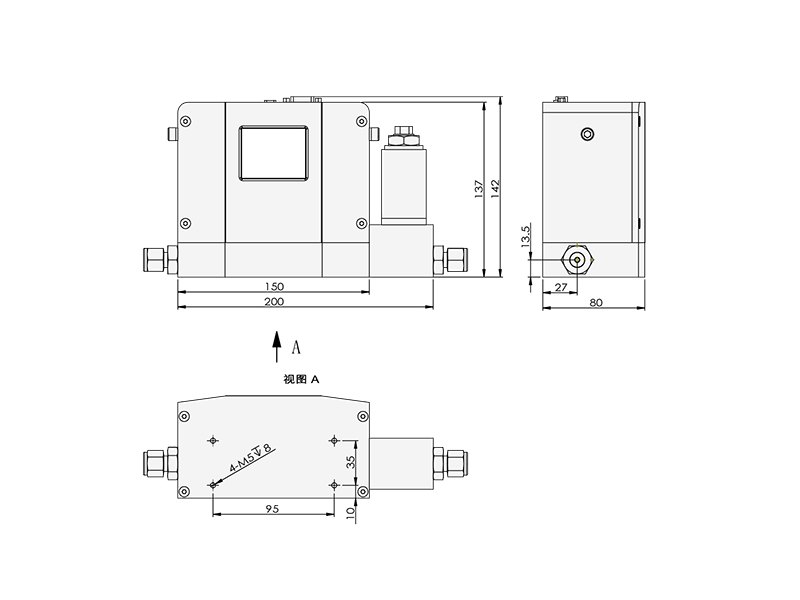

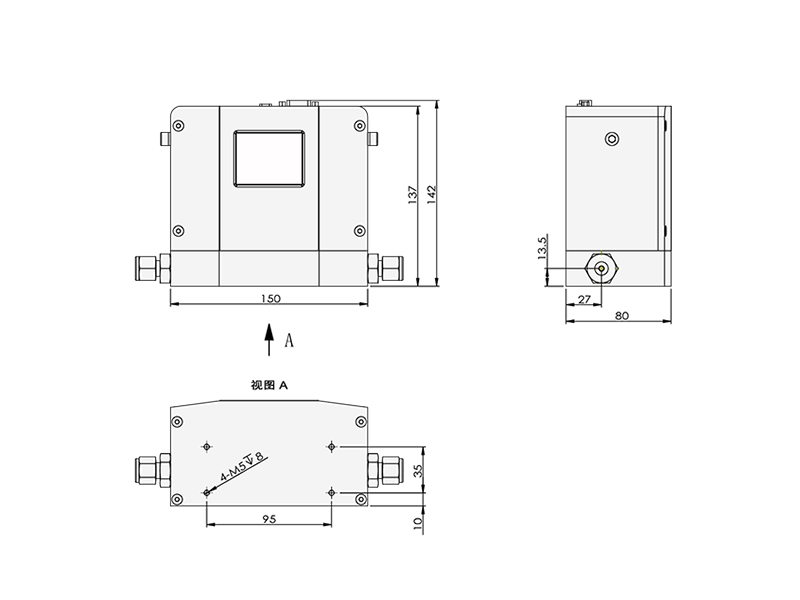

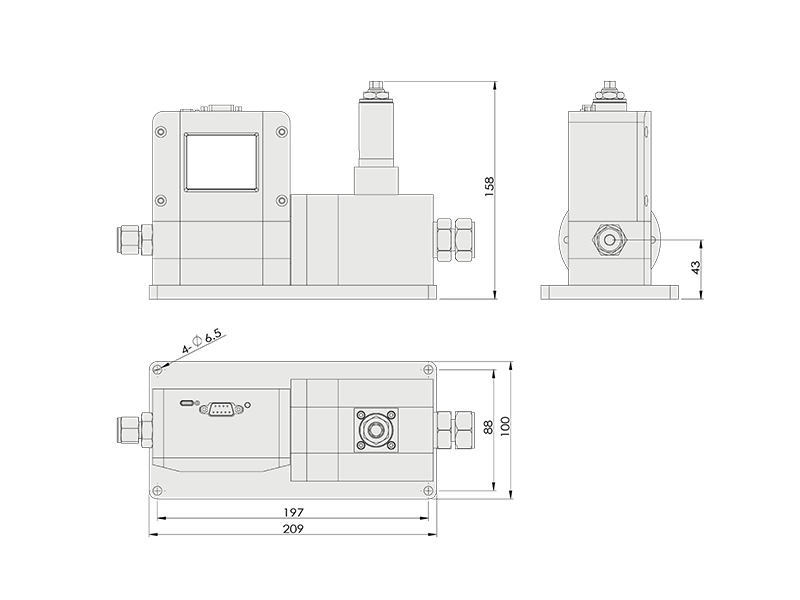

ACU20FE-SM Dimension Drawing

Product Center

ACU20FE

Product attachment:

Product Description

- Product Description

-

For ACU20FE field test video, please click the link below ↓↓↓

https://mp.weixin.qq.com/s/GjwdnfKspua8W9T2H9oXqw

I. Product Overview

◆Direct measurement of mass flow

◆Accuracy: ±0.8%F.S for gas, ±0.5% for liquid

◆No dead zone

◆Fast response and adjustment speed

◆High accuracy and good repeatability

◆Integrated PID controller for flow regulation

◆High cost performance

◆High reliability and long lifespan

◆No thermal drift, negligible temperature and time drift

◆Simultaneous output of fluid density and temperature

◆Measurable for high viscosity fluids and high-density gases

◆Insensitive to environmental vibrations

Coriolis mass flow meters are highly regarded for their measurement accuracy and insensitivity to fluid properties. The ACU20FE incorporates a uniquely shaped single-loop sensor that forms part of an oscillating system. When fluid flows through the sensor loop, the Coriolis force causes a variable phase shift, which the sensor detects and transmits to a DSP processor on the integrated circuit board for calculation. The output signal generated from this variable phase shift is strictly proportional to the actual mass flow rate, achieving unparalleled high performance even under varying conditions such as pressure, temperature, density, conductivity, and viscosity.

The ACU20FE simultaneously measures and outputs mass flow, fluid density, and temperature, providing two levels of accuracy: ±0.25% for liquid measurement and ±0.5% for gas measurement. This is sufficient to meet the needs of most customers, applicable to various laboratory experiments and complex industrial environments.

II. Product Applications

Food industry (Petro)chemical Pharmaceutical industry Fermentation equipment Semiconductor processing Fuel cell technology Various instrument analysis III. Product Parameters

Series ACU20FE Model SC

SM

LC

LM

MC

MM

BC

BM

HC

HM

Measurement Range 0-(20g/h-25kg/h) 0-(20g/h-50kg/h) 0-(50kg/h-100kg/h) 0-(100kg/h-300kg/h) 0-(300kg/h-1000kg/h) Accuracy ±0.8%F.S Gas: ±0.5%F.S, Liquid: ±0.25%F.S Linearity ±0.1%F.S Repeatability ±0.05%F.S Maximum Pressure 3MPa/10MPa Turn Down Ratio 50:1 100:1 50:1 100:1 50:1 100:1 50:1 100:1 Analog Output 0~5V、4~20mA Digital Output RS232/485, MODBUS protocol Power Supply 24VDC Communication Protocol Modbus, DeviceNet, Profinet, EtherCAT, Profibus, etc. Operating Temperature 0~70℃ Maximum Pressure 3MPa/10MPa (specified when ordering) Electrical Connection DB9 connector Display Touchscreen Leak Rate 2×10-9 Pa·m³/s Protection Level IP40 Valve Valve normally closed / Valve normally closed / Valve normally closed / Valve normally closed / Valve normally closed / Base Material Stainless steel Installation Position Any position Sealing Material Viton, Nitrile rubber, EPDM, Perfluoroether Connector Compression fitting, Pagoda, Quick-connect, VCR, Flange, etc. IV. Product Dimensions

V. Optional Matching Monitoring and Control Software (Additional charges apply)

Mass Flow Monitoring and Control System V5.0

Keyword:

Semiconductor and Microelectronics Manufacturing

Get a quote

Note: Please leave your mobile phone number or email address, and our professionals will contact you as soon as possible!