Product Center

ACU100I

Category:

Product attachment:

Product Description

- Product Description

-

I. Product Overview

◆Range: 0~180Nm/s (Standard condition: 0℃, 101.33KPa)

◆Accuracy 1%, Range ratio 100:1

◆Operating temperature: -40~400℃

◆Fast response double-sheathed sensor

◆Corrosion-resistant sensor, suitable for measuring corrosive gases

◆Full-range expert algorithm ensures measurement accuracy

The insertion gas mass flow meter uses standard precision wind tunnel calibration and adopts the King's law of thermal dissipation (cooling) effect based on the constant temperature principle. It can simultaneously display flow rate (flow), and temperature. It is sensitive to low flow rates and achieves high accuracy at high flow rates. Even at high temperatures, it can achieve good constant temperature difference and good stability.

II. Product Applications

It can measure various gases, directly outputting mass flow rate without temperature and pressure compensation. It is available in intrinsically safe and explosion-proof types, with two output options. Suitable for large-diameter, low-flow measurements, with multiple installation methods available.

Measured media: Air, natural gas, biogas, coal gas, dry chlorine, oxygen, carbon monoxide auxiliary fuel, flue gas, torch gas, hydrogen, argon and other dry gases.

III. Technical Parameters

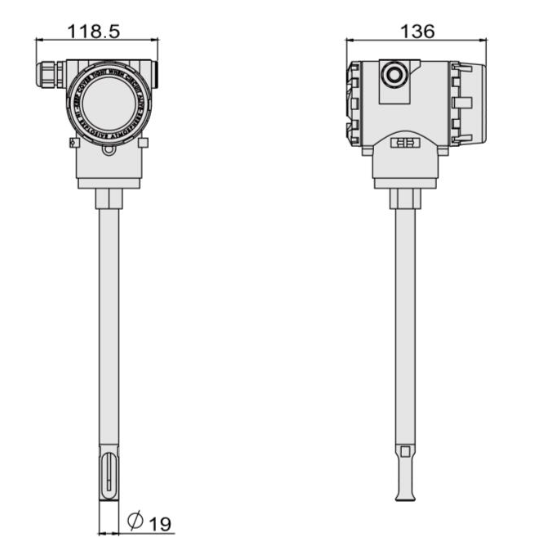

Measurement Range 0~180Nm/s Accuracy ±1% reading ±0.5% full scale Range Ratio 100:1 Response Time 3 seconds, adjustable via damping coefficient Ambient Temperature With LCD: -20~70℃, Without LCD: -40~85℃ Medium Temperature -20~175℃/-20~275℃/-20~400℃ Analog Output Two 4-20mA (flow rate, temperature) One 4-20mA with HART communication Digital Output HART and MODBUS optional Repeatability ±0.5%F.S Temperature Coefficient 0.05%/10℃ Material Compatibility Housing: Cast aluminum, epoxy resin coating, nitrile rubber O-ring Protection Level IP67 Humidity 0-100%RH Explosion-proof Grade NEPSI explosion-proof permit EX d llCT4, explosion-proof grade C Power Supply 24VDC Electromagnetic Compatibility IEC 61000-4-2~5 Process Connection Flange mounting, threaded mounting Installation Method Integrated, split Wiring Four-wire IV. Product Dimensions

Keyword:

Semiconductor and Microelectronics Manufacturing

Get a quote

Note: Please leave your mobile phone number or email address, and our professionals will contact you as soon as possible!