Product Center

ACU20CEM

ACU20CEM

Category:

Product attachment:

Product Description

- Product Description

-

I. Product Overview

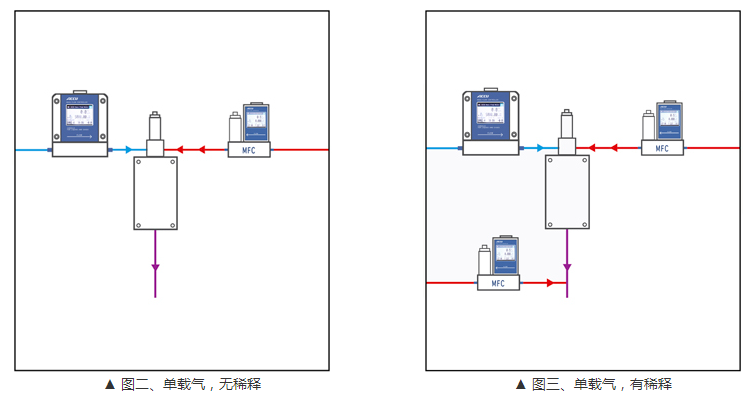

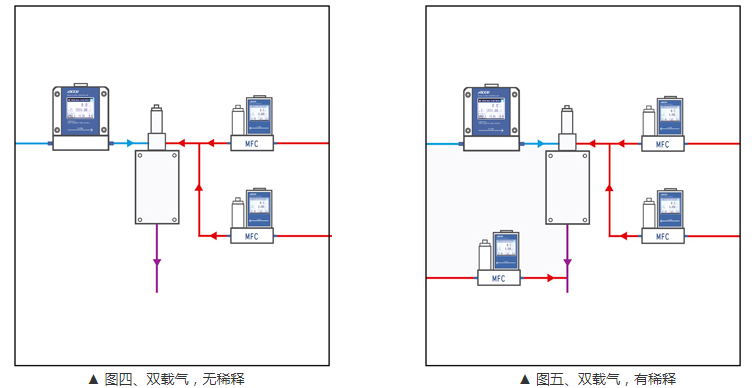

The ACCU gas-liquid mixed evaporation system consists of five parts: a liquid flow controller (for controlling the liquid source flow rate), one or more gas mass flow controllers (for controlling the carrier gas flow rate), a temperature-adjustable mixed evaporator (for liquid vaporization); an optional flow and temperature display controller (for setting flow rate and temperature), and an optional post-vaporization dilution gas flow controller (for diluting the output vapor).

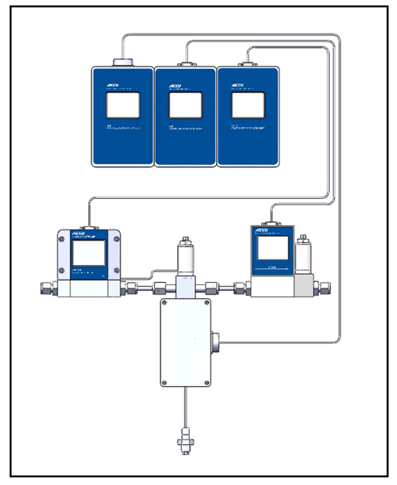

◆A typical CEM system is shown in Figure 1, where a three-way display controller connects and independently controls the liquid flow, gas flow, and evaporation temperature. A PLC and DCS system can replace the display controller, achieving centralized control through protocols such as MODBUS or DEVICENET.

◆According to site needs, one or more carrier gas flow controllers can be added to achieve multi-component carrier gas injection.

◆A three-way valve can be added to the steam outlet, connecting a gas mass flow controller to dilute the output steam.

Figure 1, Typical CEM System

II. Technical Parameters

2.1 Temperature-Controllable Mixed Evaporator

Product Model ACU20CEM Maximum Vaporization Capacity 1200g/h Pressure Rating 10MPA Maximum Temperature 300℃ Connector VCR, Compression Fitting 2.2 Flow/Temperature Display Controller

Product Model ACU20CEM Power Supply 220V Analog Signal 0-5V or 4-20mA Digital Signal MODBUS (RS232/485), PROFIBUS, DEVICENET protocols Display Type LCD with Touchscreen III. Applications

IV. Optional Matching Monitoring and Control Software (Additional charges apply)

Mass Flow Monitoring and Control System V5.0

Keyword:

Semiconductor and Microelectronics Manufacturing

Get a quote

Note: Please leave your mobile phone number or email address, and our professionals will contact you as soon as possible!